Full square spray pattern with uniform distribution.

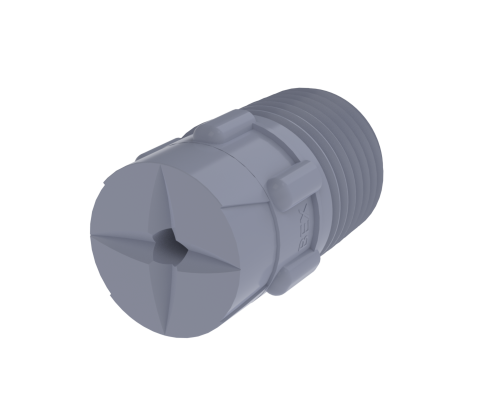

These nozzles are injection molded and feature a patented insert with larger flow passages than older styles, making them less prone to clogging. Each BEX molded nozzle is designed with a series of "knobs" that make them easier to finger tighten, especially when wet, and a small starter barrel that reduces the risk of stripping or cross-threading during installation.

| Model Number | Maximum Free Passage (inches) | Capacities at Various Pressures (USGPM) | Spray Angle | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 psi | 5 psi | 7 psi | 10 psi | 15 psi | 20 psi | 30 psi | 40 psi | 60 psi | 80 psi | 100 psi | 150 psi | 7 psi | 20 psi | 80 psi | ||

| 1/8S3.6SQ | 0.057 | 0.197 | 0.97 | 0.301 | 0.36 | 0.44 | 0.51 | 0.62 | 0.72 | 0.88 | 1.02 | 1.14 | 1.39 | 42° | 55° | 50° |

| 1/8S4.8SQ | 0.033 | 0.263 | 0.34 | 0.40 | 0.48 | 0.59 | 0.68 | 0.83 | 0.96 | 1.18 | 1.36 | 1.52 | 1.86 | 50° | 65° | 60° |

| 1/8S6SQ | 0.051 | 0.33 | 0.42 | 0.50 | 0.60 | 0.73 | 0.85 | 1.04 | 1.20 | 1.47 | 1.70 | 1.90 | 2.32 | 60° | 65° | 60° |

| 1/4S6SQ | 0.051 | 0.33 | 0.42 | 0.50 | 0.60 | 0.73 | 0.85 | 1.04 | 1.20 | 1.47 | 1.70 | 1.90 | 2.32 | 60° | 65° | 60° |

| 1/4S10SQ | 0.064 | 0.55 | 0.71 | 0.84 | 1.00 | 1.22 | 1.41 | 1.73 | 2.00 | 2.45 | 2.83 | 3.2 | 3.9 | 61° | 67° | 60° |

| 1/4S12SQ | 0.064 | 0.66 | 0.85 | 1.00 | 1.20 | 1.47 | 1.70 | 2.08 | 2.40 | 2.94 | 3.4 | 3.8 | 4.6 | 71° | 76° | 69° |

| 1/4S14SQ | 0.091 | 0.77 | 0.99 | 1.17 | 1.40 | 1.71 | 1.98 | 2.42 | 2.80 | 3.4 | 4.0 | 4.4 | 5.4 | 78° | 85° | 75° |