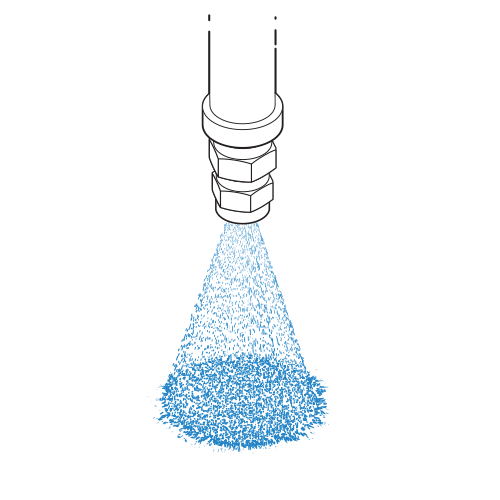

Full cone spray pattern with uniform distribution throughout the cone.

Two-piece body + removable insert. Available in male and female threads. The nozzle contains a patented insert with larger flow passages than older styles, and is less susceptible to clogging.

| Model Number | Maximum Free Passage (inches) | Capacities at Various Pressures (USGPM) | Spray Angle | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Female | Male | 3 psi | 5 psi | 7 psi | 10 psi | 15 psi | 20 psi | 30 psi | 40 psi | 60 psi | 80 psi | 100 psi | 150 psi | 7 psi | 20 psi | 80 psi | |

| 1/8FGS1 | 1/8GS1 | 0.033 | 0.055 | 0.071 | 0.084 | 0.100 | 0.123 | 0.141 | 0.173 | 0.200 | 0.245 | 0.283 | 0.32 | 0.39 | -- | 55° | 52° |

| 1/8FGS1.5 | 1/8GS1.5 | 0.046 | 0.082 | 0.106 | 0.126 | 0.150 | 0.184 | 0.212 | 0.260 | 0.300 | 0.37 | 0.42 | 0.47 | 0.58 | -- | 65° | 57° |

| 1/8FGS2 | 1/8GS2 | 0.051 | 0.110 | 0.141 | 0.167 | 0.200 | 0.245 | 0.283 | 0.35 | 0.40 | 0.49 | 0.57 | 0.63 | 0.77 | 54° | 59° | 60° |

| 1/8FGS3 | 1/8GS3 | 0.051 | 0.164 | 0.212 | 0.251 | 0.300 | 0.37 | 0.42 | 0.52 | 0.60 | 0.73 | 0.85 | 0.95 | 1.16 | 50° | 53° | 60° |

| 1/8FGS3.5 | 1/8GS3.5 | 0.051 | 0.192 | 0.248 | 0.293 | 0.35 | 0.43 | 0.50 | 0.61 | 0.70 | 0.86 | 0.99 | 1.11 | 1.36 | 48° | 58° | 61° |

| 1/8FGS5 | 1/8GS5 | 0.064 | 0.274 | 0.35 | 0.42 | 0.50 | 0.61 | 0.71 | 0.87 | 1.00 | 1.22 | 1.41 | 1.58 | 1.94 | 60° | 75° | 70° |

| 1/4FGS5 | 1/4GS5 | 0.081 | 0.274 | 0.35 | 0.42 | 0.50 | 0.61 | 0.71 | 0.87 | 1.00 | 1.22 | 1.41 | 1.58 | 1.94 | 58° | 68° | 62° |

| 1/8FGS6 | 1/8GS6 | 0.064 | 0.33 | 0.42 | 0.50 | 0.60 | 0.73 | 0.85 | 1.04 | 1.20 | 1.47 | 1.70 | 1.90 | 2.32 | 67° | 72° | 50° |

| 1/4FGS6.5 | 1/4GS6.5 | 0.091 | 0.36 | 0.46 | 0.54 | 0.65 | 0.80 | 0.92 | 1.13 | 1.30 | 1.59 | 1.84 | 2.06 | 2.52 | 48° | 56° | 48° |

| 1/4FGS7.5 | 1/4GS7.5 | 0.091 | 0.41 | 0.53 | 0.63 | 0.75 | 0.92 | 1.06 | 1.30 | 1.50 | 1.84 | 2.12 | 2.37 | 2.90 | 55° | 65° | 63° |

| 1/4FGS8.5 | 1/4GS8.5 | 0.091 | 0.47 | 0.60 | 0.71 | 0.85 | 1.04 | 1.20 | 1.47 | 1.70 | 2.08 | 2.40 | 2.69 | 3.3 | 58° | 65° | 62° |

| 3/8FGS9.5 | 3/8GS9.5 | 0.102 | 0.52 | 0.67 | 0.79 | 0.95 | 1.16 | 1.34 | 1.65 | 1.90 | 2.33 | 2.69 | 3.00 | 3.7 | 58° | 68° | 75° |

| 1/4FGS10 | 1/4GS10 | 0.091 | 0.55 | 0.71 | 0.84 | 1.00 | 1.22 | 1.41 | 1.73 | 2.00 | 2.45 | 2.83 | 3.2 | 3.9 | 60° | 65° | 62° |

| 3/8FGS10 | 3/8GS10 | 0.102 | 0.55 | 0.71 | 0.84 | 1.00 | 1.22 | 1.41 | 1.73 | 2.00 | 2.45 | 2.83 | 3.2 | 3.9 | 55° | 65° | 50° |

| 1/4FGS14 | 1/4GS14 | 0.091 | 0.77 | 0.99 | 1.17 | 1.40 | 1.71 | 1.98 | 2.42 | 2.80 | 3.4 | 4.0 | 4.4 | 5.4 | 78° | 78° | 60° |

| 3/8FGS15 | 3/8GS15 | 0.102 | 0.82 | 1.06 | 1.26 | 1.50 | 1.84 | 2.12 | 2.60 | 3.00 | 3.7 | 4.2 | 4.7 | 5.8 | 63° | 65° | 76° |

| 3/8FGS18 | 3/8GS18 | 0.102 | 0.99 | 1.27 | 1.51 | 1.80 | 2.20 | 2.55 | 3.12 | 3.6 | 4.4 | 5.1 | 5.7 | 7.0 | 85° | 88° | 76° |

| 3/8FGS20 | 3/8GS20 | 0.102 | 1.10 | 1.41 | 1.67 | 2.00 | 2.45 | 2.83 | 3.5 | 4.0 | 4.9 | 5.7 | 6.3 | 7.7 | 76° | 72° | 75° |

| 3/8FGS22 | 3/8GS22 | 0.114 | 1.21 | 1.56 | 1.84 | 2.20 | 2.69 | 3.11 | 3.8 | 4.4 | 5.4 | 6.2 | 7.0 | 8.5 | 76° | 78° | 76° |

| 1/2FGS16 | 1/2GS16 | 0.144 | 0.88 | 1.13 | 1.34 | 1.60 | 1.96 | 2.26 | 2.77 | 3.2 | 3.9 | 4.5 | 5.1 | 6.2 | 55° | 60° | 55° |

| 1/2FGS25 | 1/2GS25 | 0.144 | 1.37 | 1.77 | 2.09 | 2.50 | 3.06 | 3.5 | 4.3 | 5.0 | 6.1 | 7.1 | 7.9 | 9.7 | 68° | 73° | 65° |

| 1/2FGS32 | 1/2GS32 | 0.144 | 1.75 | 2.26 | 2.68 | 3.2 | 3.9 | 4.5 | 5.5 | 6.4 | 7.8 | 9.1 | 10.1 | 12.4 | 80° | 90° | 75° |

| 1/2FGS40 | 1/2GS40 | 0.162 | 2.19 | 2.83 | 3.3 | 4.0 | 4.9 | 5.7 | 6.9 | 8.0 | 9.8 | 11.3 | 12.6 | 15.5 | 86° | 90° | 81° |